In this article

What is Piping and Instrumentation Diagram?

Piping and instrumentation diagram, also called P&ID, is a diagram used to show a graphical display of a complete system. It includes all piping, instruments, valves and equipment that the system consist of. Through a P&ID, you can get the following information:

- The mechanical and electrical details of a given system or process,

- Piping information such as sizes and material specifications,

- Continuation flags leading to the connecting P&ID's,

- Flow arrows, DCS alarm types

- The connection types from the controllers to the field devices.

How to Read P&IDs

Here are a few aspects that you should pay attention to while reading a piping and instrumentation diagram. You need to know what P&ID symbols mean in a P&ID and tell how each symbol is constructed using graphical elements and connecting lines. If you manage to do this, it wouldn't be difficult for you to read a piping and instrumentation diagram at all.

#1 Know the Letter and Number Combinations of a P&ID

Letter and number combinations appear inside each graphical element and letter combinations are defined by the ISA standard. Numbers are user assigned. The first letter defines the measured or initiating variables such as Analysis (A), Flow (F), Temperature (T), etc. with succeeding letters defining readout, passive, or output functions such as Indicator (I), Record (R), Transmit (T), and so forth.

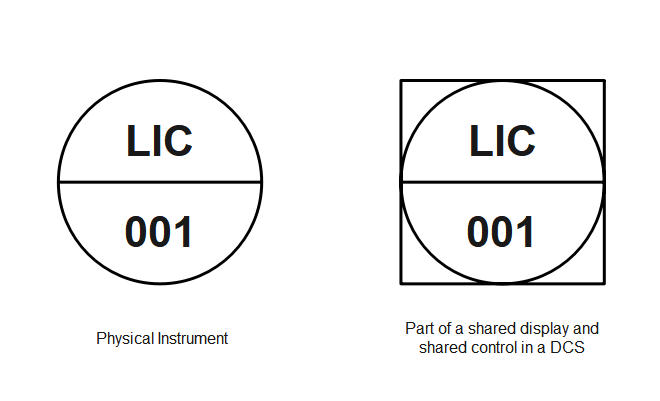

Tag numbers are a combination of alphabets and numbers with varying lengths aiding in identifying the device, what it controls, the type of device, and the number with what it is registered on the P&ID. Physical instruments are indicated by a tag number and a circle around it. These numbers are also used to locate the position of equipment.

The order and letters in tag numbers are highly specified and unique for each device. The first digit/letter specifies the factors controlled and monitored by the device, while the second digit indicates the type of device. The letters constituting from 3,4 and 5 further elaborate the device’s function and hint about the following few numbers in the series.

Common Abbreviations Used in P&ID

Abbreviations are introduced in a P&ID to keep the diagrams concise and simple. The table below constitutes some commonly used abbreviations.

| AC | Analysis Controller | PB | Push-button |

| AE | Analyzer Element | P/I | Pneumatic To Current Converter |

| AAH | Analysis Alarm [High] | POV | Pneumatically Operated Valve |

| BE | Burner Element | pHT | pH Transmitter |

| BDV | Blowdown Valve | PSE | Rupture Disk |

| CR | Conductivity Recorder | PR | Pressure Recorder |

| ES | Electrical Switch | PZV | Pressure Relief Valve |

| FIT | Flow Indicator Transmitter | RC | Ratio Controller |

| FY | Computer, Relay, Amplifier or I/P Converter, etc. in Flow Loop | RO | Restriction Orifice |

| I/I | Current Indicator | RTD | Resistance Temperature Detector |

| KI | Clock/Timer | SA | Speed Alarm |

| LCV | LCV Level Control Valve | SD | Shutdown Panel |

| LIT | Level Indicator Transmitter | SV | Solenoid Valve |

| LO | Lock Open | TA | Temperature Alarm |

| MCC | Motor Control Center | TCV | Temperature Control Valve |

| MT | Motion Transmitter | TH | Thermostat |

| MTU | Master Terminal Unit | US | Utility Station |

| NC | Normally Closed | WE | Weight Measuring Element |

| NO | Normally Open | WS | Water Supply |

| PA | Pressure Alarm | ZV | Safety Shut-down (Pilot) valve |

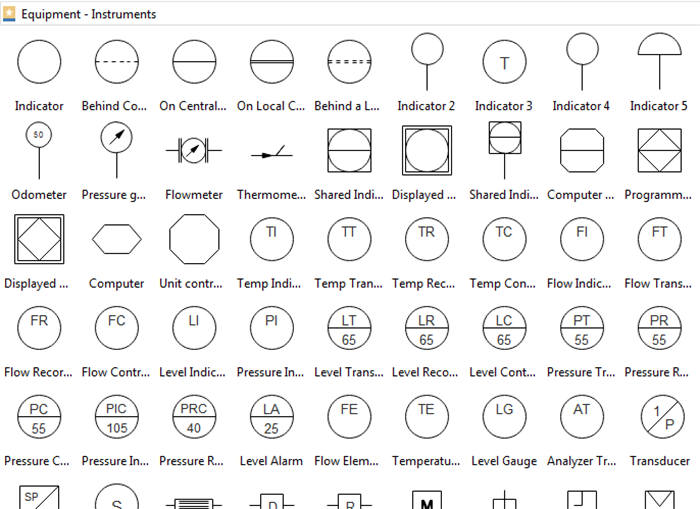

#2 Identify and Understand Standard Equipment -Instruments

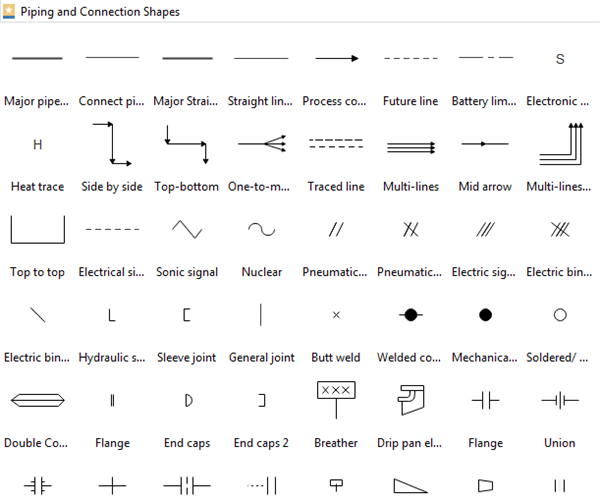

It is also important to know how to read its symbols and shapes in the drawing. EdrawMax provides all kinds of symbols required in P&IDs.

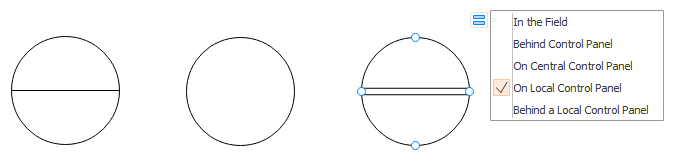

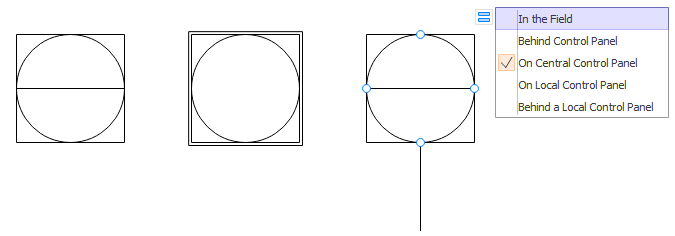

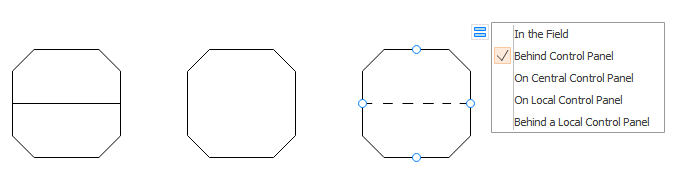

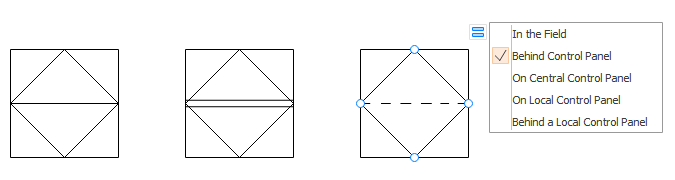

All the instruments in a P&ID are marked by a circle with an assigned tag number and line inside it. The tag number helps in identifying the device, whereas the line is the location indicator. Lines are classified into different types, each describing the device's location with respect to the field. Given below are the types of lines used in a P&ID.

Instruments Location

- No line: A simple circle indicates that the device is in the field and is a locally mounted instrument. The device is observable in the field and is accessed by the operator.

- Solid Line: A solid line in the center signifies that the instrument is placed in a primary location in the control room. The instrument is visible on the front of the panel or video display.

- Dashed Line: The dashed line specifies that the instrument is in a secondary position in the control room and is not accessible by the operator. The instrument is not visible on the front of the panel or video display.

- Double Solid Line: A double solid line tells that it is in a primary position in the local control center and is operator accessible at the panel front or console.

- Double Dashed Line: A double dashed line describes that the instrument is in a secondary position in the local control center and is not operator accessible. The device is located in the field cabinet and is not visible on the front of the panel or the video display.

Shared Display and Shared Control

Shared display means when the same information can be viewed and accessed from different locations in a network. Shared control indicates that the user can interact with the system and modify the operational conditions remotely. For representing an instrument with a shared control and display system, take the tag number and draw a square around it. This indicates that now the instrument can be accessed remotely in a Distributed Control System (DCS).

According to ISA S5.1, there are mainly 4 four graphical elements: discrete instruments, shared control/display, computer function, and programmable logic controller. Discrete instruments are indicated by circular elements. Shared control/display elements are circles surrounded by a square. Computer functions are indicted by a hexagon and programmable logic controller (PLC) functions are shown as a triangle inside a square. These shapes represent both the physical or the software devices. In either case , it implies all the shapes needed in a piping and instrumentation diagram. You will see these shapes anytime a system is shown on the P&ID.

- Discrete instruments

- Shared control/display

- Computer function

- Programmable logic controller

#3 Learn to Use Graphical Elements and Connecting Lines

The connections between elements is a way for engineers to identify a particular pipe in a standardized way. And different color indicates different pipes to avoide confusion. Adding a single horizontal bar across any of the four graphical elements indicates the function resides in the primary location category. A double line indicates an auxiliary location, devices located behind a panel-board in some other inaccessible location are shown with a dashed horizontal line.

The connection lines on a P&ID elaborate about the associations between instruments: how they connect to each other and the type of signal being transmitted. For example, a solid line signifies the connection is via pipes, while a dashed line indicates the electrical transmission. Knowing about the symbols is essential to understand the P&ID charts correctly. Here are the primary line types that are used to connect different devices/instruments.

| Major Process Piping |  |

| Minor Process Piping |  |

| Electrical Signal |  |

| Mechanical Link |  |

| Electromagnetic (Guided) Wave |  |

| Electromagnetic (Unguided) Wave |  |

| Pneumatic Signal |  |

| Software or Data Link |  |

| Capillary Tubing |  |

| Hydraulic Tubing |  |

If you want to know more about Piping and Instrumentation Diagram or EdrawMax, welcome to experience.

EdrawMax is a powerful, all-in-one, and yet easy-to-use diagramming tool that enables users to visualize the ideas effortlessly.

EdrawMax provides beginners and pros the cutting-edge functionalities to build professional-looking diagrams easier, faster, and cheaper! It allows you to create more than 280 types of diagrams and should be an excellent Visio alternative.

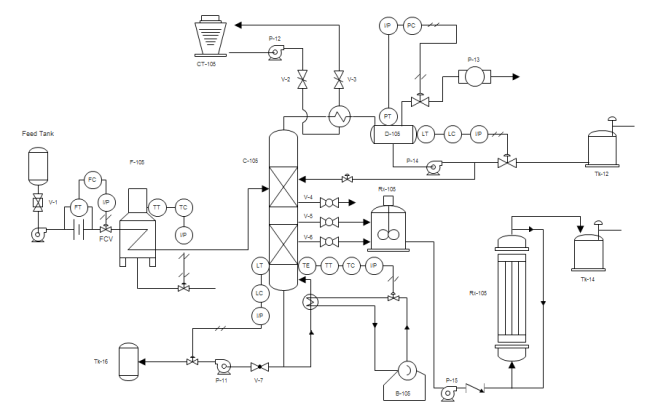

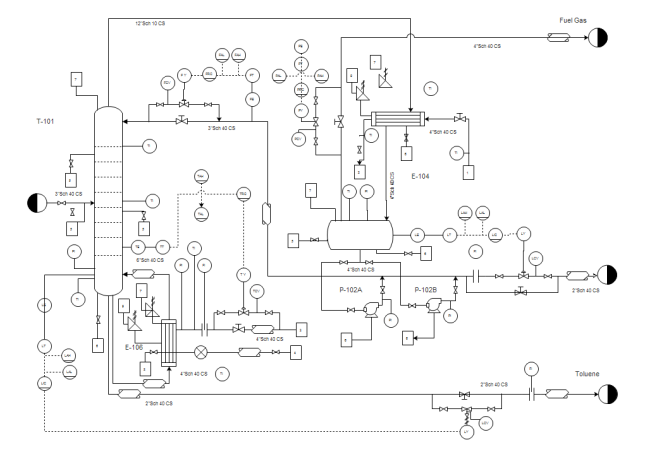

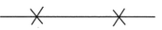

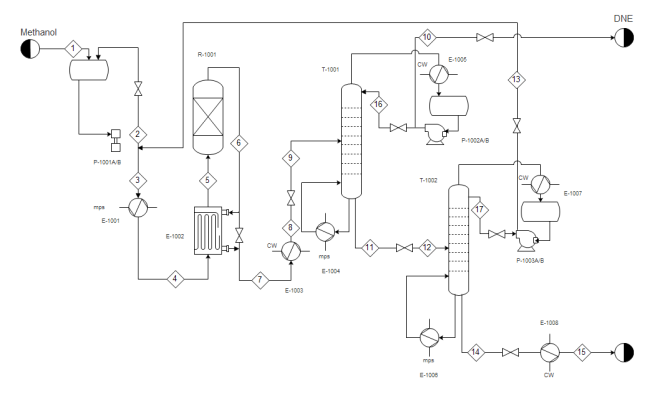

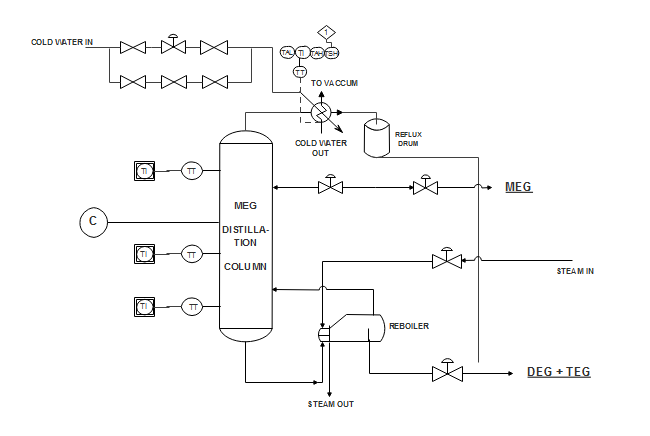

Piping and Instrumentation Diagram Examples

Here are some popular P&ID examples created by EdrawMax, which you can free download and customize on your needs. To get more P&ID examples and templates, you can visit our Template Community.

- Plant P&ID

- Water Boiling Process P&ID

- System P&ID

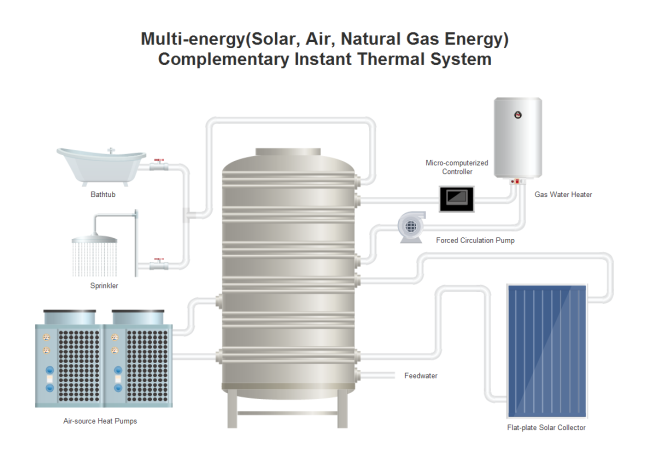

- Thermal System P&ID

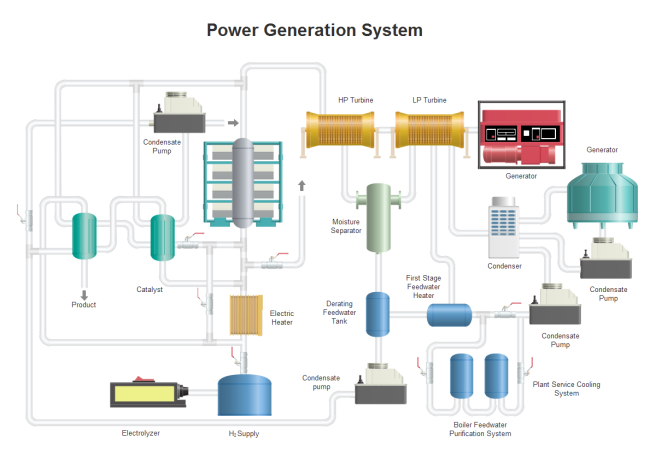

- Power Generation P&ID

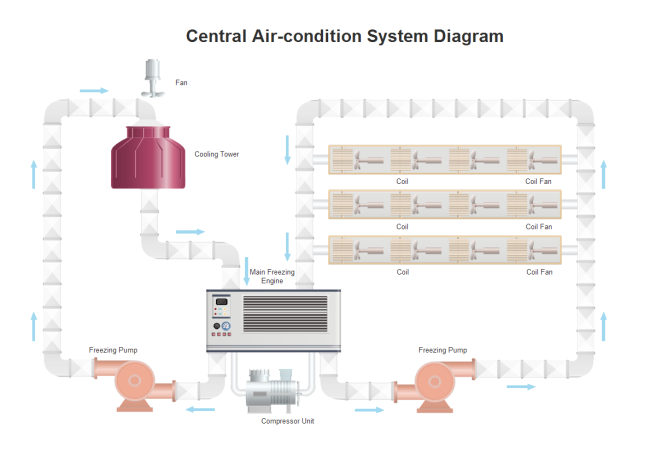

- Air Condition Process P&ID

EdrawMax is the versatile diagram software that integrates 100% functionality and libraries of all other drawing products.